More than 30,000 table saw injuries occur each year.

But there are ways to prevent these injuries, and the techniques could be mandated by the U.S. government.

Table saws are common tools used to cut materials quickly and accurately, but they come with the risk of serious injury.

“This is definitely one of the most dangerous tools in a factory,” said Matt Baxter, assistant manager at Woodcraft in Tulsa. This is because it draws people in.” .

He uses tools such as table saws on a daily basis.

“I've always been very careful about what I'm doing and where my hands are,” he said.

Manager Laura Cain said some people aren't as careful as Baxter and could pay a price.

“So many people are coming in. I'm not kidding. They're going to come in with missing fingers,” she said.

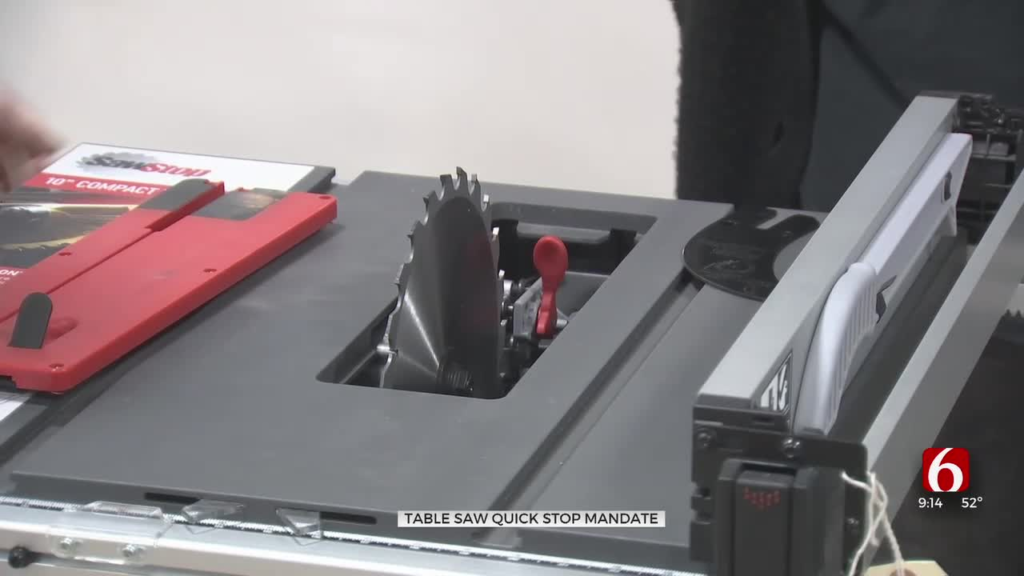

However, there are techniques to prevent these injuries. Manufactured by a company called SawStop, the blade immediately stops rotating when it detects contact with your skin.

It takes seconds for a knife to seriously injure someone, but thanks to safety features like the one in SawStop, what was once a serious injury is now only a minor one.

“The brake cartridge contains electrical current that flows through the blades, using electrical current naturally present in the body to complete the circuit,” Baxter says.

Baxter says it saves fingers and hands.

This technology has been around for a while, but businesses aren't required to use it.

But the Consumer Product Safety Commission is currently proposing a rule that would require all table saws sold in the United States to have safety brakes.

“It’s safer, much safer,” Kane said.

Manufacturers have opposed the move, saying it would raise the price of table saws for consumers. But Mr Kane and Mr Baxter argue that is a better price to pay than losing a finger and facing hospital bills.

“Once it's out there, it's going to be really good,” Cain said.

The Consumer Product Safety Commission voted in October to move forward with the mandate, and the commission expects to approve it later this year.